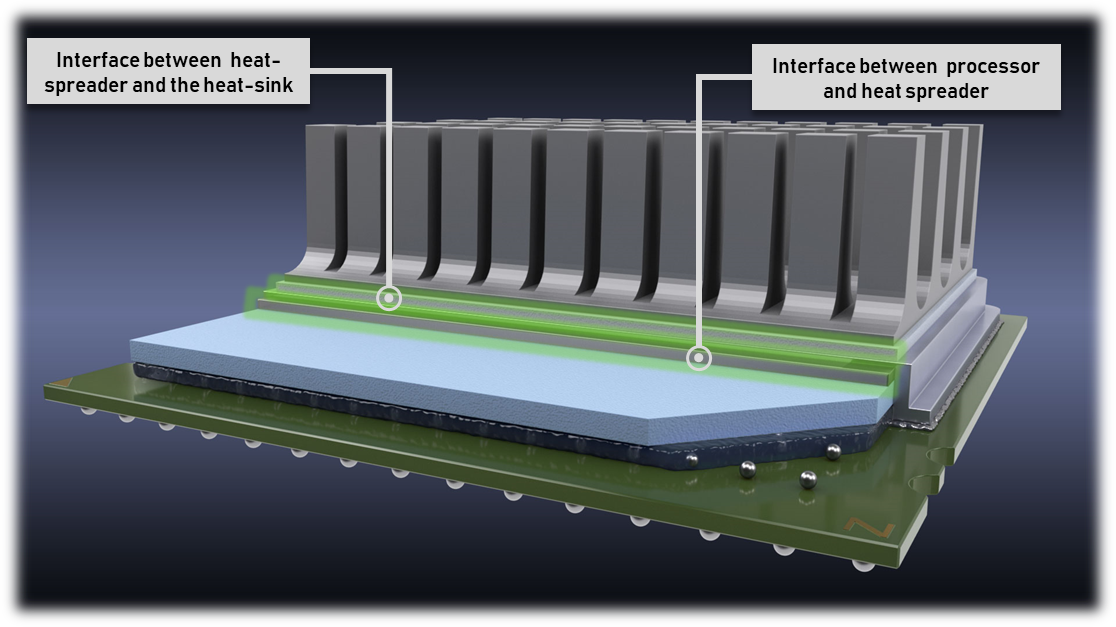

To address the thermal demands of today’s leading-edge semiconductor devices, NAMICS has developed a portfolio of high conductive thermal interface materials (TIM) to meet a wide range of applications. These innovative materials provide exceptional heat dissipation for next generation semiconductor packages allowing designers to push the limits of the device capabilities.

Due to the uniqueness of each application, NAMICS offers a variety of solutions to handle both the current and future needs. In addition to providing unmatched thermal conductivity, these materials offer industry leading reliability and performance that is compatible with standard manufacturing processes. The end results are a collection of materials capable of meeting the consumer demand for higher product performance.

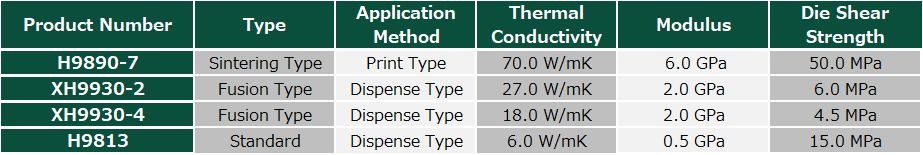

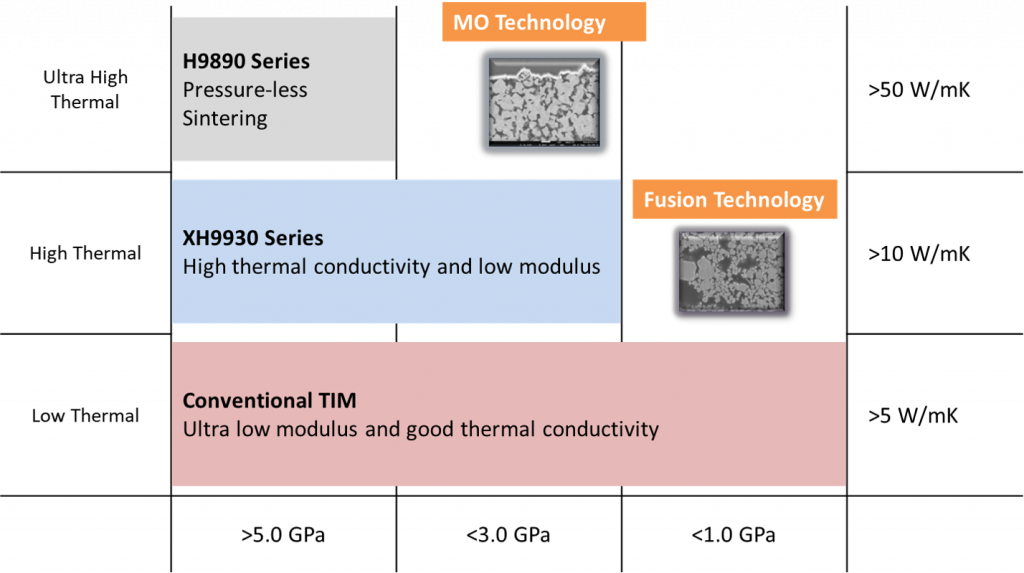

NAMICS offers three types of high conductive TIM

MO Technology

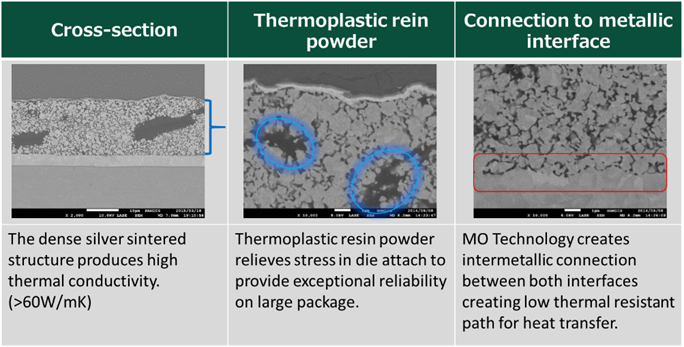

MO Technology is silver / metal organic compound developed by NAMICS. When combined with dispersant and solvent, it produces a pressure-less, low temperature sintering structure.

Sintering Technology

Intermetallic bonding between sintered silver and the metallized interfaces significantly improved heat transfer throughout the interface, making this bond very low thermal resistance.

Low Modulus Technology

When Cu based lid and large die are used in the package, the stress at the die attach material drastically increase due to the C.T.E mismatch between the die and the lid or substrate. The large C.T.E mismatch leads to delamination and crack in the die attach area. By adding thermoplastic resin powder to the paste, the modulus is significantly reduced to a low as 6 GPa and reliability improved, yet the thermal conductivity remains relatively high, in a range og 60W/mK.

This novel technology provides durable die-attach material with industry leading thermal and electrical conductivity for the next generation Thermal Interface Materials.

Fusion Technology

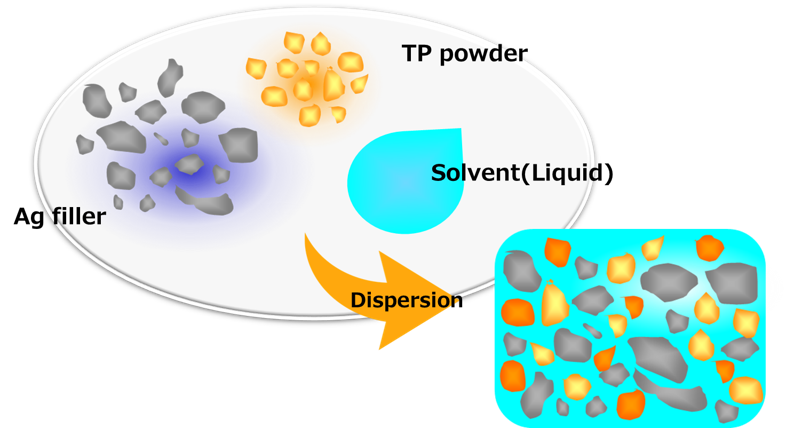

Fusion Technology combines thermoplastic powder (TP) with Ag filler to create a high thermal conductive adhesive with low modulus.

High Thermal Conductivity

Liquid resin system will hinder the fusion of silver particles reducing connection and conductivity. Fusion Technology utilizes proprietary thermoplastic powder that melts and penetrates between silver fillers. Result is high thermal conductivity.

Low Modulus

After proprietary thermoplastic powder penetrates space between silver, it functions as an elastomer to relieve stress and reduce low modulus. Final product offers industry leading thermal conductivity combined with low modulus to create a ductile thermal interface material for the most demanding applications.

Property Overview