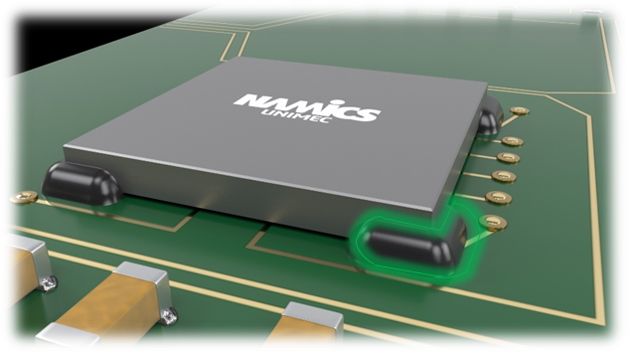

NAMICS Corner Bond provides an alternative to complete underfill process. The material is dispensed to all four corners of the CSP/BGA to reinforce component and improve reliability. Corner bonded provides a simplified manufacturing process for CSP/BGA, eliminating the capillary flow time and providing more reliability than unreinforced bumps.

Features of corner bond materials are:

- Simplified process with no capillary underfill flow process

- Low dispensing volume for an economical solution to BGA/CSP reinforcement

- High throughput with fast cure system

- No void issue