As technology evolves, so does the need for components that can facilitate innovation. With todays focus on smart surfaces, advanced techniques and materials are what makes it all possible. Printed electronics make such advances possible, eliminating the need for large, bulky, multi-part circuitry, but the benefits dont stop there.

As technology evolves, so does the need for components that can facilitate innovation. With todays focus on smart surfaces, advanced techniques and materials are what makes it all possible. Printed electronics make such advances possible, eliminating the need for large, bulky, multi-part circuitry, but the benefits dont stop there.

In-Mold Electronics (IMEs) are 70 percent lighter than conventionally-manufactured electronics. Since there are no buttons and wires, the potential for breakage is significantly decreased, making IME parts more durable.

In addition to a 30 percent reduction in production costs, manufacturers enjoy a shorter assembly time and an almost infinite number of new design possibilities for applications that include automotive, medical, appliances, wearables, smart home consumer technology, and much more besides.

Benefits of Stretchable Inks

In the area of stretchable inks for IME applications, NAMICS is leading the way. Our superior functional inks offer leading class stretch performance that outshines our competitors versions.

Compared to competitors inks, NAMICS inks showed minimal resistance change after forming, with no noticeable cracks or deformation. With excellent adhesion and compatibility to polycarbonate substrates, our functional inks are designed for standard printing equipment with quick drying times and are capable of deep drawing and forming configurations that results in a high manufacturing output.

Other benefits include:

- Parts are lightweight and efficient, featuring up to 90 percent less depth and 80 percent less weight

- Highly durable

- Easy to update production processes, both cosmetic and electrical

- Mass-production ready, ideal for high-speed manufacturing equipment

Industry-Leading Innovation

Far from a new player in this space, NAMICS has been innovating for more than 70 years. Our new line of functional inks is designed for smart technology, providing a way to make the next generation of smart surfaces possible.

Our stretchable inks include both silver and carbon-based conductive inks and dielectric inks suitable for a range of electronic applications, giving designers and engineers a platform to ideate and bring new products to market quickly, setting the standard for future innovation.

Leading Class Stretch Performance

With the growing demand for smarter, more compact, affordable, and portable tech, stretchable inks are fast becoming an essential manufacturing tool.

As an industry leader in this area, NAMICS continues to outperform, providing companies with the technology they need to push the boundaries of innovation and open up new possibilities that, even in recent times, have been unattainable due to cost, durability, and reliability concerns.

Our stretchable inks include:

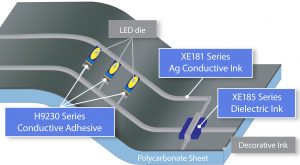

- Silver (Ag) conductive inks, XE181 series, offering high electrical conductivity to create the necessary electrical connections

- Carbon-based conductive inks, XE182 series, that can be used to protect Ag conductive inks in highly moisture-resistant environments, or to create simple PTC (Positive Temperature Control) heaters with low voltage

- Dielectric inks, XE185 series, that feature a uniform, pinhole-free layer with high insulation, allowing crossover layers or insulating Ag conductive ink layers

NAMICS also offers a Conductive Bonding Adhesive, H9230 series, for bonding rigid components to the interconnects.

To learn more about NAMICS, stretchable inks, and how we can become your innovation partner, reach out today.